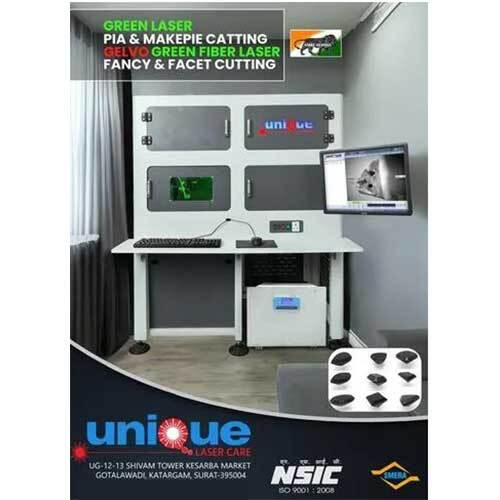

Green Gelvo Fancy Diamond Cutting Machine

Green Gelvo Fancy Diamond Cutting Machine Specification

- Drive Motor

- Brushless AC Motor

- Product Type

- Fancy Diamond Cutter

- General Use

- Diamond Industry

- Material

- Hardened Steel, Aluminium Alloy

- Type

- Diamond Cutting Machine

- Capacity

- 75 stones/hour

- Weight (kg)

- 140 kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- Cutting Speed

- 3000 RPM

- Cutting Thickness

- 0.2 mm 25 mm

- Cutting Function

- Precision Diamond Cutting

- Cooling System

- Integrated Water Cooling

- Drive Type

- Electric Servo Motor

- Voltage

- 220-240V, 50/60Hz

- Dimension (L*W*H)

- 750 x 510 x 920 mm

- Feature

- High Efficiency, Energy Saving, Smooth Finish

- Color

- Green

- Motor

- Precision High-Speed Motor

- Mechanical Precision

- 0.01 mm

- Software Detail

- Advanced Proprietary Software

- Cutting Method

- Rotary Blade Cutting

- Control System

- CNC Control Panel

- Cutting Area

- 250 x 250 mm

- Cutting Material

- Rough & Fancy Diamonds

- Safety Features

- Overload Protection, Emergency Stop

- Installation

- Pre-assembled, Ready to Use

- Operating Temperature Range

- 10C 40C

- Power Consumption

- 1.8 kW

- Lubrication System

- Automatic Oil Lubrication

- Noise Level

- < 65 dB

- Display Interface

- Touchscreen LCD

Green Gelvo Fancy Diamond Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Foot

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Asia, Australia, Central America, South America, Eastern Europe, Africa

- Main Domestic Market

- All India, Rajasthan, East India, Uttar Pradesh, Tripura, Dadra and Nagar Haveli, Manipur, Andaman and Nicobar Islands, Chhattisgarh, Kerala, Punjab, Goa, Jharkhand, West Bengal, Andhra Pradesh, West India, Pondicherry, Assam, Delhi, Meghalaya, Chandigarh, Daman and Diu, Central India, Lakshadweep, Bihar, Nagaland, Odisha, Himachal Pradesh, Madhya Pradesh, Uttarakhand, Telangana, Gujarat, Maharashtra, North India, Karnataka, Tamil Nadu, Sikkim, Arunachal Pradesh, , Haryana, Jammu and Kashmir, South India, Mizoram

About Green Gelvo Fancy Diamond Cutting Machine

It is the Diamond Processing System doing fancy shape cutting like heart, cushion, pear, oval, marquise, princess, cushion, and emerald with the one-time fixing of the stone. This all-in-one machine can perform table sawing, bruiting, and pavilion coning as well as fancy shaping in a single setup.

It is the Diamond Processing System doing fancy shape cutting like heart, cushion, pear, oval, marquise, princess, cushion, and emerald with the one-time fixing of the stone. This all-in-one machine can perform table sawing, bruiting, and pavilion coning as well as fancy shaping in a single setup.

Innovative Technology for Precise Diamond Cutting

The Green Gelvo machine combines an electric servo drive with proprietary advanced software to enable computerized, high-efficiency diamond cutting. Its CNC system guarantees accuracy, while automatic features like oil lubrication and integrated water cooling enhance performance, producing a flawless, smooth finish for each diamond shape.

Built for Safety and Ease of Operation

Designed to simplify operation, the machine arrives pre-assembled and ready to use. Safety is prioritized through overload protection and an emergency stop mechanism, while the LCD touchscreen interface offers intuitive control. Its quiet, fully automatic workflow ensures a safe and efficient cutting environment.

Durability and Versatility for Industry Needs

Constructed with robust materials like hardened steel and aluminium alloy, the Green Gelvo machine is built to meet the rigorous demands of diamond manufacturers and exporters. With a wide cutting thickness range and adaptable rotary blade system, it is versatile for various diamond types and industrial requirements.

FAQ's of Green Gelvo Fancy Diamond Cutting Machine:

Q: How does the Green Gelvo Fancy Diamond Cutting Machine achieve high-precision cutting?

A: The Green Gelvo utilizes a CNC control system paired with a precision high-speed servo motor and rotary blade, enabling mechanical accuracy up to 0.01 mm. Its advanced proprietary software optimizes every cut, ensuring consistent quality and smooth finishes for both rough and fancy diamonds.Q: What safety measures are included in this machine?

A: Safety is ensured through features like overload protection, an easily accessible emergency stop button, and an automatic oil lubrication system, which helps prevent overheating and mechanical failure during operations.Q: When and where is this machine typically installed and used?

A: The Green Gelvo machine, manufactured and supplied from India, is delivered fully pre-assembled and ready for immediate operation. It is primarily used in professional diamond cutting workshops and factories serving the diamond export and manufacturing industry.Q: Which materials and thicknesses can the machine cut?

A: Designed for diamond processing, the Green Gelvo can handle both rough and fancy diamonds within a thickness range of 0.2 mm to 25 mm, delivering precise results across various diamond shapes and sizes.Q: What are the main benefits of using this machine for diamond cutting?

A: Users benefit from high cutting speeds (up to 75 stones per hour), energy-efficient operation (1.8 kW), minimal noise, a fully automatic workflow, and superior cutting quality. The integrated cooling and lubrication systems also ensure longevity and reliability.Q: How does the machine operate and what kind of interface does it have?

A: Operators control the machine via a touchscreen LCD interface and a CNC control panel, supported by advanced proprietary software. The computerized system enables efficient, user-friendly programming and operation for all diamond cutting processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Cutting Machine Category

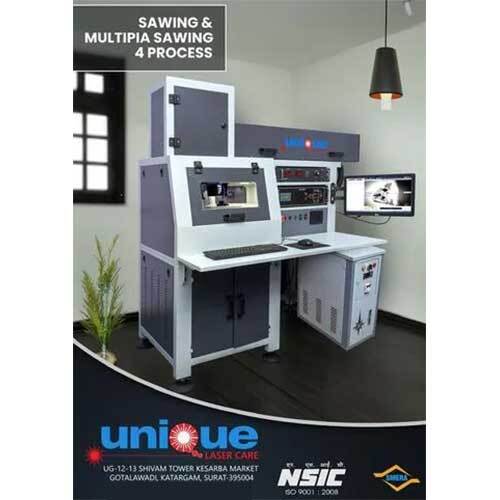

Gelvo Multipia Diamond Cutting Machine

Price 1250000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Diamond Cutting

Automatic : Yes

Control System : Digital

Product Type : Diamond Cutting Machine

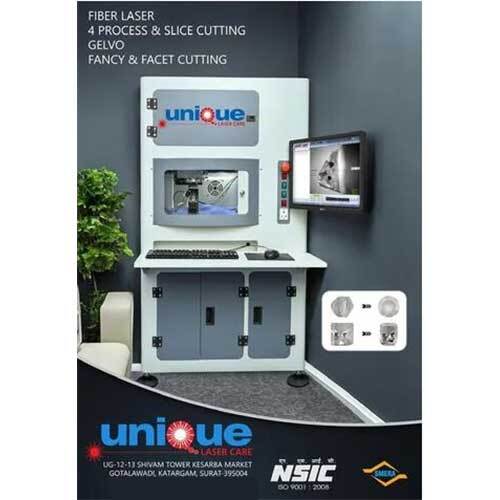

4 Process diamond Laser Cutting Machine

Price 600000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Industrial

Automatic : Yes

Control System : Manual

Product Type : 4 Process diamond Laser Cutting Machine

Fancy Diamond Cutting Machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Automatic : Yes

Control System : Manual

Product Type : Diamond Cutting Machine

Green Diamond Laser Cutting Machine

Price 2400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Automatic : Yes

Control System : Manual

Product Type : Green Laser Cutting Machine

Send Inquiry

Send Inquiry Send SMS

Send SMS