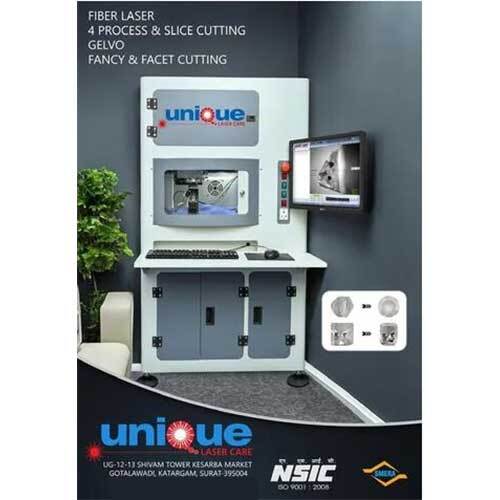

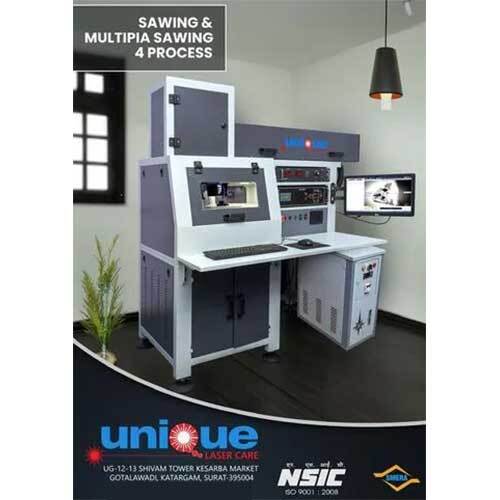

4 Process diamond Laser Cutting Machine

4 Process diamond Laser Cutting Machine Specification

- Product Type

- 4 Process diamond Laser Cutting Machine

- General Use

- Industrial

- Material

- Steel

- Weight (kg)

- 170 Kilograms (kg)

- Computerized

- Yes

- Automatic

- Yes

- Control System

- Manual

- Cutting Function

- Semi Automatic

- Cooling System

- Water Chiller

- Drive Type

- Electric

- Voltage

- 220-240 Volt (v)

- Color

- Gray

- Warranty

- Yes

- Software Detail

- nothing

4 Process diamond Laser Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 2 Week

- Packaging Details

- on condition

- Main Export Market(s)

- Asia, Australia, South America, Eastern Europe, Africa

- Main Domestic Market

- All India

About 4 Process diamond Laser Cutting Machine

Introducing our 4 Process diamond Laser Cutting Machine, a versatile solution for industrial cutting needs. Equipped with advanced laser technology, it offers precise cutting, engraving, marking, and welding capabilities in one machine. Crafted for durability and efficiency, it ensures consistent performance across various Diamond fabrication tasks. With user-friendly controls and customizable settings, it provides flexibility and ease of operation. Streamline your production process and achieve superior results with our 4 Process Diamond Laser Cutting Machine, the ultimate tool for metalworking professionals.

Superior Cooling with Water Chiller

This laser cutting machine is equipped with an advanced water chiller, maintaining optimal operating temperatures during prolonged use. The cooling system prevents overheating, enhancing cutting performance and extending the lifespan of both lasers and core components. This feature ensures consistent and efficient operation in demanding industrial environments.

Semi-Automatic Precision for Steel Cutting

Engineered for semi-automatic functionality, the 4 Process Diamond Laser Cutting Machine combines user-friendly manual controls with precise computerized features. It allows operators to achieve accurate, repeatable cuts in steel material, ideal for various manufacturing or fabrication needs. The blend of manual and automatic functionalities supports both experienced professionals and newcomers.

Industrial Reliability and Versatile Usage

Built from durable steel and designed for general industrial use, this machine stands out in terms of reliability and versatility. Its gray exterior withstands harsh conditions, while the combination of automatic and manual controls makes it suitable for a range of applications, including manufacturing, exporting, and supplying within India.

FAQs of 4 Process diamond Laser Cutting Machine:

Q: How does the water chiller system benefit the laser cutting process?

A: The integrated water chiller efficiently regulates the temperature of the machine during cutting operations, minimizing the risk of overheating. This not only boosts the machines performance but also prolongs the life of laser components, ensuring stable and precise cutting outputs for industrial tasks.Q: What materials can be processed with this diamond laser cutting machine?

A: This machine is specifically designed for cutting steel material with high precision. Its durable construction and advanced laser technology make it suitable for a wide range of industrial steel cutting applications.Q: When is this machine most effective for industrial use?

A: The 4 Process Diamond Laser Cutting Machine delivers optimal results during extended cutting operations and in environments where consistent, high-quality performance is required. Its cooling system and semi-automatic functions ensure reliability even under continuous use.Q: Where can the machine be installed and used?

A: This machine is suitable for installation in industrial plants, fabrication workshops, and manufacturing facilities. Its robust design and voltage compatibility (220240V) make it adaptable to various industrial settings across India.Q: What is the cutting process utilized by this machine?

A: The machine employs a semi-automatic laser cutting process that allows operators to manage cutting parameters both manually and through computerized controls, resulting in precise and efficient steel cutting.Q: How user-friendly is the control system for operators?

A: The control system features a combination of manual and computerized controls, enabling simple setup and adjustment. This dual approach allows for flexibility, making the machine accessible to both experienced technicians and new users.Q: What are the primary benefits of choosing this laser cutting machine for your business?

A: Key benefits include improved cutting accuracy, reduced downtime due to the efficient water chiller, robust steel construction for durability, and versatile control options. Additionally, the warranty and after-sales support make this machine a reliable investment for industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Cutting Machine Category

Gelvo Multipia Diamond Cutting Machine

Price 1250000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Diamond Cutting Machine

Control System : Digital

General Use : Diamond Cutting

Automatic : Yes

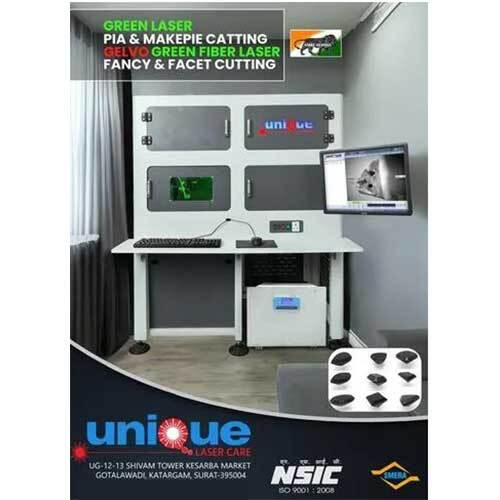

Green Gelvo Fancy Diamond Cutting Machine

Price 145000 INR / Piece

Minimum Order Quantity : 1 Foot

Product Type : Fancy Diamond Cutter

Control System : CNC Control Panel

General Use : Diamond Industry

Automatic : Other, Fully Automatic

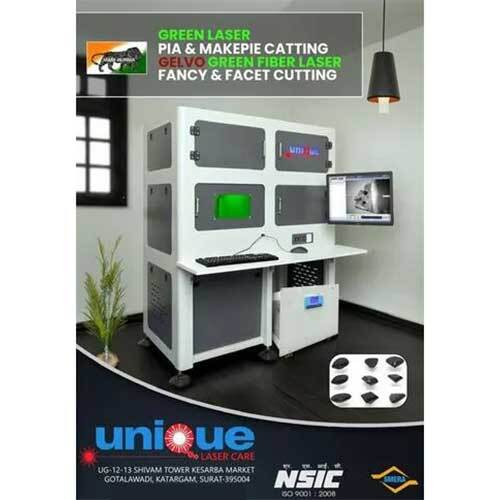

Gelvo Fancy And Makepia Diamond Cutting Machine

Price 1650000 INR / Piece

Minimum Order Quantity : 1 Foot

Product Type : Automatic Diamond Cutting

Control System : PLC with Touchscreen

General Use : Diamond shaping and faceting

Automatic : Other, Full Automatic Operation

Fancy Diamond Cutting Machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Diamond Cutting Machine

Control System : Manual

General Use : Industrial

Automatic : Yes

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free