Gelvo Fancy And Makepia Diamond Cutting Machine

Gelvo Fancy And Makepia Diamond Cutting Machine Specification

- Drive Motor

- AC Servo Motor

- Product Type

- Automatic Diamond Cutting

- General Use

- Diamond shaping and faceting

- Material

- Stainless Steel and Alloy

- Type

- Diamond Cutting Machine

- Capacity

- 80100 stones/day

- Weight (kg)

- 185 kg

- Computerized

- Yes

- Automatic

- Full Automatic Operation

- Cutting Speed

- 0.53 m/min adjustable

- Cutting Thickness

- Up to 8 mm

- Cutting Function

- Automated diamond cutting for various shapes

- Cooling System

- Integrated Water Cooling

- Drive Type

- Servo Motor Drive

- Voltage

- 220 V AC

- Dimension (L*W*H)

- 900 x 650 x 1400 mm

- Feature

- High precision, stable performance

- Color

- Blue & Silver

- Motor

- 2 HP high-efficiency motor

- Mechanical Precision

- 0.01 mm

- Software Detail

- Gelvo Makepia Software

- Cutting Method

- Wet & Dry Cutting

- Control System

- PLC with Touchscreen

- Cutting Material

- Natural & Synthetic Diamonds

- Cutting Area

- 420 x 90 mm

- Display

- 7" Color Touchscreen Panel

- Packaging Type

- Wooden Box

- Finish

- Corrosion-resistant Coating

- Noise Level

- < 72 dB

- Lubrication System

- Automatic Oil Feeder

- Operating Temperature

- 10C40C

- Safety Features

- Emergency Stop, Interlock Guards

- Spindle Speed

- 2800 RPM

- Input Frequency

- 50/60 Hz

- Work Table Type

- Rotary with Clamping Jaws

- Application

- Industrial Diamond Cutting Factory

- Power Consumption

- 1.5 kW

- Interface

- USB and Ethernet

Gelvo Fancy And Makepia Diamond Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Foot

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Asia, Australia, South America, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India, Bihar, Pondicherry, Dadra and Nagar Haveli, Manipur, Meghalaya, Rajasthan, Tripura, West Bengal, Daman and Diu, Central India, Maharashtra, Uttarakhand, Andhra Pradesh, East India, Uttar Pradesh, Telangana, Kerala, Nagaland, Assam, Andaman and Nicobar Islands, Lakshadweep, Odisha, West India, Chandigarh, Delhi, Tamil Nadu, Himachal Pradesh, Punjab, Haryana, Karnataka, , Jharkhand, Mizoram, North India, Sikkim, Goa, South India, Arunachal Pradesh, Madhya Pradesh, Gujarat, Jammu and Kashmir, Chhattisgarh

About Gelvo Fancy And Makepia Diamond Cutting Machine

Using advanced optics, Sarine's scanning devices take accurate 360 degree-images of semi-polished and polished diamonds, and then utilize an extensive range of parameters to determine cut and recut options that truly maximize the potential and yield of the polished result.

It is the Diamond Processing System doing fancy shape cutting like heart, cushion, pear, oval, marquise, princess, cushion, and emerald with the one-time fixing of the stone. This all-in-one machine can perform table sawing, bruiting, and pavilion coning as well as fancy shaping in a single setup.

Advanced Precision Engineering

Equipped with servo motor drive and computerized controls, the Gelvo Fancy And Makepia Diamond Cutting Machine delivers mechanical precision up to 0.01 mm. Its rotary work table with clamping jaws secures diamonds for accurate shaping and faceting, ensuring consistent quality with every cut.

User-Friendly Automation

Enjoy full automatic operation via the 7" color touchscreen and PLC control system. Operators can easily adjust settings such as spindle speed, cutting speed, and cutting thickness, streamlining diamond cutting and reducing manual intervention without compromising safety through features like emergency stops and interlock guards.

Maximized Productivity and Safety

Cutting up to 100 stones per day, this machine integrates an automatic oil feeder and water cooling system to ensure high throughput and extended equipment longevity. Emergency stop mechanisms and corrosion-resistant materials prioritize operator safety and minimize maintenance downtime in industrial environments.

FAQ's of Gelvo Fancy And Makepia Diamond Cutting Machine:

Q: How do I operate the Gelvo Fancy And Makepia Diamond Cutting Machine safely?

A: To operate the machine safely, ensure you follow all manufacturer guidelines. Engage all provided safety features, including emergency stop and interlock guards, before beginning operation. The PLC touchscreen makes it easy to monitor and control cutting parameters safely.Q: What materials and shapes can the machine cut?

A: This diamond cutting machine is designed for both natural and synthetic diamonds. It supports automated cutting for a variety of shapes, allowing for precise faceting and shaping according to industrial standards.Q: When should I perform maintenance on the machine?

A: Routine maintenance can be minimized thanks to the automatic oil feeder and corrosion-resistant coating. However, regular inspection of moving parts, lubrication system, water cooling, and safety mechanisms is advised based on the manufacturer's recommendations or after intense daily use.Q: Where is this diamond cutting machine best used?

A: It is ideal for use in industrial diamond cutting factories, particularly those specializing in shaping and faceting large volumes of stones requiring both wet and dry cutting processes.Q: What is the process for cutting diamonds on this machine?

A: Load the diamond onto the rotary work table with clamping jaws, select or program the cutting function via the touchscreen using Gelvo Makepia Software, and initiate automated cutting. The machine's servo drive and PLC control ensure consistent speed and precision throughout the procedure.Q: How does the machine ensure high-quality, precise cuts?

A: Equipped with a mechanical precision of 0.01 mm, servo motor drive, and PLC-based computerized controls, the machine maintains stable performance. Its automatic lubrication and integrated water cooling systems further enhance cutting accuracy and tool longevity.Q: What are the key benefits of using this diamond cutting machine?

A: Users benefit from high productivity (up to 100 stones/day), precise and consistent cutting results, reduced human error due to automation, enhanced operator safety, reliable performance under varied industrial conditions, and extended machine life thanks to corrosion-resistant materials and robust construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Cutting Machine Category

Gelvo Multipia Diamond Cutting Machine

Price 1250000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Digital

General Use : Diamond Cutting

Product Type : Diamond Cutting Machine

Automatic : Yes

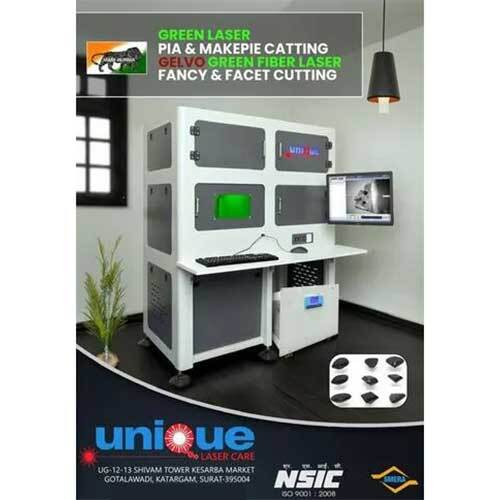

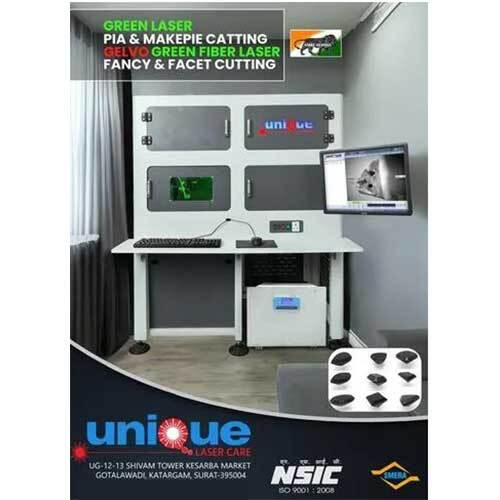

Green Gelvo Fancy Diamond Cutting Machine

Price 145000 INR / Piece

Minimum Order Quantity : 1 Foot

Control System : CNC Control Panel

General Use : Diamond Industry

Product Type : Fancy Diamond Cutter

Automatic : Other, Fully Automatic

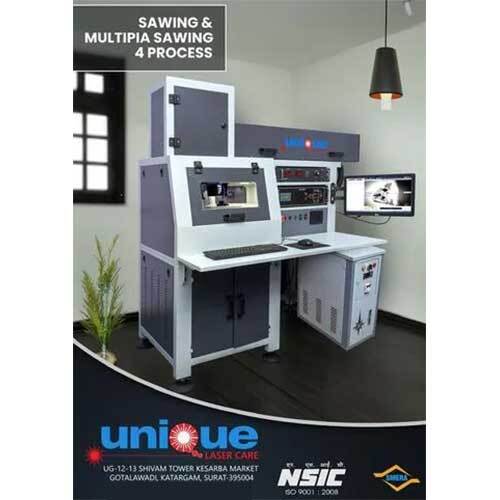

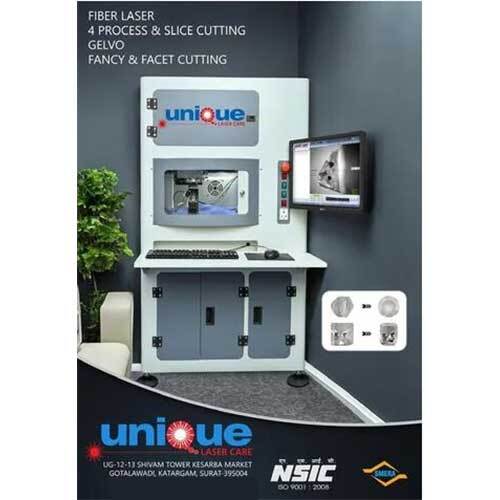

4 Process diamond Laser Cutting Machine

Price 600000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

General Use : Industrial

Product Type : 4 Process diamond Laser Cutting Machine

Automatic : Yes

Fancy Diamond Cutting Machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Manual

General Use : Industrial

Product Type : Diamond Cutting Machine

Automatic : Yes

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free